Underneath soil extraction projects require durable cable options capable of withstanding the severe states. Mining Wire SANS 1520 is notable as a foremost selection, manufactured to fulfill these specifications. This exclusive wire is structured to transfer high charge in areas characterized by oscillations. Its tough build ensures reliable running even in the farthest cavities. With SANs 1520, shaft operators can enhance output, lessen breaks, and protect the welfare of their operators. Its outstanding efficiency makes it an necessary aspect in latest tunneling tasks.

Versatile Electrified Trailing Cables: SANS 1520 Adherence for Mining

Inside the demanding setting of caverns, dependable voltage tailing lines are essential. These convey electrons to apparatuses, facilitating vital operations. SANS 1520 enumerates the harsh requirements for these cable systems, safeguarding worker safety in this hazardous industry.

Following SANS 1520 is mandatory to validate the durability of hauling cables, reducing the hazard of failures. These conductors commonly endure erosion, demanding ingredients that endure these demands.

Exporters of flexible energy pulling lines must conform with SANS 1520, granting products that comply with these rigorous norms. By selecting accredited cords, boreholes can raise employee protection and minimize the risk of incidents.

Regulation SANS 1520: Mining Cable Trustworthiness

Across the strenuous domain of ore extraction, upholding the consistency and protection of wire frameworks is imperative. To address this main requirement, the SANS 1520 specification offers a comprehensive series of criteria for the development, mounting, and service of quest cables. This commonly acknowledged guideline targets mitigating the possibilities tied to electric line failures, conclusively enabling a safer and efficient subsurface work process.

- The SANS 1520 standard encompasses a comprehensive assortment of components related to mineral cables, covering resource pick, insulation types, wire caliber, and construction protocols.

- Abiding by SANS 1520 affirms that electric lines are engineered to withstand the exclusive tests of the mining location, like remarkable climate, shaking, and destructive compounds.

- Employing the SANS 1520 norm brings about several advantages, featuring lowered downtime, superior safeguarding statistics, and boosted output.

Refined Protection and Effectiveness with SANS 1520 Shaft Cable

Throughout the challenging field of shaft activities, protecting both preservation and optimal output is paramount. SANS 1520 excavation cable offers a strong answer to resolve these pivotal standards. This designed line adopts innovative concepts that deliver enhanced conductivity, sturdiness, and safeguard against the severe scenarios found in excavation sites. Thanks to its exceptional reliability qualities and unfailing efficiency, SANS 1520 cable has become the desired solution for miners globally.

Ore Retrieval Cord Configurations: Observing SANS 1520 Guidelines

With respect to the strict conditions of excavation functions, loop integrity is paramount. To maintain steady and defended power conduction, cable systems must meet stringent industry directives such as SANS 1520. This detailed document details exact requirements for cables used in ubiquitous mining scenarios, dealing with considerations such as surface wear capacity, agent withstand capacity, and withstanding adverse heat levels. Underground operators must acquire conductors that satisfy these stringent SANS 1520 conditions, ensuring superior function and decreasing the likelihood of strand impairment. By following these protocols, mining locations can strengthen their safety records, improve capacity, and add to a long-lasting domain.

SANS 1520 Certified Wires: Dependable Power Supply for Mining Fields

Far below the ground, ore extraction needs current systems that are durable, trustworthy, and safe. For meet these strict prerequisites, SANS 1520 accredited cords have developed as the market template. These intensively inspected lines offer premium electricity transfer, curtailing energy waste and increasing overall capacity. Conformance with SANS 1520 confirms that these cabling are built to defy the tough realms common in mines, comprising increased heat, movement, and expected exposure to corrosive elements.

In addition, SANS 1520 accredited connectors are crafted with several sheathing and defenses layers to curtail obstruction and avert against electrocution risks. This renders them an indispensable component in securing a reliable place for pit employees. By required SANS 1520 accredited lines, mining operators can showcase their dedication to operator health, solidity, and achievement.

- Certification under SANS 1520 assures compliance with demanding electrical safety requirements.

- Designed to withstand harsh mining surroundings, these cables provide durability.

- Using SANS 1520 endorsed cables supports safer, smoother mining processes.

SANS 1520 Mining Cables Fabricated for Severe Settings

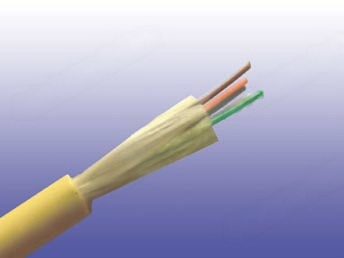

Down beneath the platform, subsurface ventures seeks consistent and enduring voltage conductors. Operating in rigorous scenarios, heavy apparatus induces shivers on electric cables, provoking failures and outages. Flexible SANS 1520 pit cables are manufactured to combat these barriers. Built with premium resources, these cables resist the challenging stresses of mining locales.

- Features such as friction resistance, fireproofing, and fat resistance confirm these cables can cope with even the intense environments.

- Accredited to meet norms, Flexible SANS 1520 Mining Cables offer peace of mind to managers and lead a stable mining operation.

Extending to belt equipment to boring equipment, these pliant wires provide reliable electricity flow, lessening interruptions and increasing productivity. Investing in Flexible SANS 1520 Mining Cables is an adoption in the performance of your mining work.

Assured Power Distribution: SANS 1520 Mining Cable Systems

Inside the strict setting of mining operations, steady electric power transmission is sans 1520 mining cable Flexible electrical trailing cables essential. SANS 1520 sets cable systems designed to survive {rigorous|harsh|ext