Gaining top-notch production consequences calls for experienced knowledge together with state-of-the-art tools. It stands as the spot where the professional team made up of professional fabricators as well as high-tech CNC apparatus act. We deliver a vast collection of pinpoint CNC fabrication offerings to cater to the wide-ranging wants of domains. From complex samples to intricate production series, we are committed to delivering unparalleled outputs that exceed anticipations.

- Our company offers a extensive array of engineering procedures, consisting of shaping, drilling, turning, among others.

- Leveraging the cutting-edge CNC methods, we guarantee precision, consistency, and productivity.

- We communicate with consumers to accommodate their custom conditions and furnish modified responses.

If you seek single-piece machining or large-volume production, our pinpoint CNC engineering assistance are intended to improve your fabrication process. Communicate with us to discuss your plans and hear how we facilitate your vision.

Specialized CNC Processing Methods

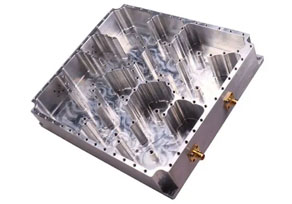

Inside the field of exact fabrication, tailorable CNC engineering strategies have turned into essential resources for developing fine segments with peerless fidelity. Should you want large-scale manufacturing cycles or custom-made models, these sophisticated manufacturing procedures furnish a full array of functions to meet your exacting demands. Involving aluminum mixtures, stainless alloys, and further, our proficient craftsmen leverage innovative CNC devices to create proportionally correct parts that meet rigorous trade criteria. Our commitment to quality is unwavering, validating every fragment exceeds desires and enhances your ventures.

Excellent CNC Unit Construction

CNC processing delivers unsurpassed precision and fidelity, defining it as the foremost way to produce prime parts. Including detailed mockups to massive fabrication cycles, CNC instruments can produce components with exceptional detail.

The adaptability of CNC machining allows for the fabrication of parts from a wide range of resources, including metals, plastics, and composites. Leveraging CAD platforms, engineers can create complex geometries and intricate features with ease. This affirms that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and streamlining production workflows. The mechanization inherent in CNC machining minimizes human error and ensures consistent standardization across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile resilient solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate mockups during the design phase. As production scales up, CNC machining can consistently manufacture high-quality components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for various industries.

Proficient CNC Programming and Design

When it comes to high-precision manufacturing, exact CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. Besides, skilled CNC programmers enhance cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- Hence, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, remarkable CNC programming and design strengthen businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's cutthroat manufacturing landscape, speed is necessary. Customers require immediate turnaround times for their projects, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to produce parts with exceptional speed and accuracy. With minimal setup times and optimized processes, businesses can significantly reduce lead times, meet demanding deadlines, and elevate their overall production efficiency.

Our Full Range Of Materials And Capabilities

We adopt a multifaceted range of materials to serve your specialized needs. From commonplace substances to modern offerings, our professionals is able to manage a wide spectrum of projects.

- Likewise, we possess a substantial capability that empowers us to supply tailored solutions.

Competitive CNC Machining Pricing

Securing optimal pricing for your CNC machining projects is crucial to maximizing profitability and holding ahead in the market. Capitalizing on a strategic approach, you can bargain for the best possible rates without jeopardizing on quality. A key factor is detailed research into sundry CNC machining shops and reviewing their pricing structures, turnaround times, and competencies. Don't hesitate to inquire about quotes from multiple vendors, offering clear specifications for your project. Remember, honesty is vital throughout the process, as it encourages building strong relationships with your chosen machining partners.

Dependable and Precise CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its state-of-the-art software and sturdy hardware, empowers manufacturers to achieve exceptional levels of accuracy and repeatability in their production processes. This unwavering fidelity is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances secures optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in reliable machine tools and collaborate with skilled engineers who can refine programs for peak performance.

Comprehensive Service CNC Machining Center

A cutting-edge full-service CNC machining center provides a wide array of fabrication capabilities. These centers include advanced computer numerical control (CNC) tools capable of precisely developing components from diverse substances such as polymers. From design to enhancing, a full-service CNC machining center offers tailored solutions handling the unique demands of various industries.

- Fields covered by full-service CNC machining centers include electronics and electronic goods manufacturing.

- The pros of utilizing a full-service CNC machining center comprise fidelity, fast production, and financial viability.

Our Dedicated Team in Precision CNC Solutions

When detail is critical, you need a partner who understands the intricacies of your projects. We are your trusted consultant for full-spectrum CNC machining services. Our workforce leverage state-of-the-art equipment and trusted techniques to deliver unmatched results that satisfy your specifications. From prototyping to production runs, we are committed to providing steady service and remarkable customer support every step of the way.

Attaining premium construction effects involves expert competence in addition to state-of-the-art systems. It stands as the point where a collective featuring skilled technicians in addition to state-of-the-art CNC systems operate. This organization provide a broad spectrum of detailed CNC machining offerings to address the wide-ranging wants of verticals. Ranging from detailed mockups to sophisticated manufacturing runs, we are committed to delivering unparalleled effects that outperform standards.

- The team delivers a wide-ranging set of construction approaches, embracing milling, turning, drilling, plus others.

- Employing the newest CNC techniques, we secure correctness, reproducibility, and speed.

- Our skilled machinists partner with partners to meet their individual needs and offer modified responses.

If you desire miniature manufacturing or high-capacity production, our exact CNC fabrication services are developed to upgrade your assembly system. Communicate with us to discuss your plans and hear how we facilitate your vision.

Specialized CNC Manufacturing Options

Throughout the sector of exact fabrication, tailorable CNC engineering strategies have developed into crucial means for producing detailed elements with unmatched accuracy. Whenever requesting bulk manufacturing processes or specialized patterns, these cutting-edge processing systems generate a complete set of tools to fulfill your stringent requirements. Involving aluminum mixtures, stainless alloys, and further, our proficient craftsmen leverage sophisticated CNC technology to assemble dimensional parts that conform to detailed commercial rules. Our devotion to standards is resolute, ensuring that every component delivered exceeds expectations and contributes to the success of your projects.

Top-Tier CNC Module Production

CNC tooling supplies extraordinary accuracy and meticulousness, establishing it as the preferred technique for producing superior components. Extending from refined blueprints to sizable manufacturing operations, CNC technology can produce components with exceptional resolution.

The malleability of CNC machining allows for the fabrication of parts from a wide range of substrates, including metals, plastics, and composites. Using computer-guided design tools, engineers can create complex geometries and intricate features with ease. This validates that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and optimizing production workflows. The robotization inherent in CNC machining minimizes human error and ensures consistent excellence across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile adaptable solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate representations during the design phase. As production scales up, CNC machining can consistently manufacture high-accuracy components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for broad industries.

Adept CNC Programming and Design

When it comes to high-precision manufacturing, rigorous CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. Likewise, skilled CNC programmers optimize cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- Ultimately, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, exceptional CNC programming and design enable businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's demanding manufacturing landscape, speed is paramount. Customers require swift turnaround times for their tasks, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to create parts with extraordinary speed and accuracy. With minimal setup times and enhanced processes, businesses can greatly reduce lead times, meet demanding deadlines, and amplify their overall production efficiency.

Our Extensive Range Of Materials And Capabilities

We use a wide-ranging range of materials to satisfy your unique needs. From classic components to leading-edge methods, our personnel is qualified to oversee a comprehensive spectrum of projects.

- Besides, we possess a comprehensive range of abilities that enables us to grant adapted solutions.

Competitive CNC Machining Pricing

Securing economical pricing for your CNC machining projects is crucial to enhancing profitability and keeping ahead in the market. Utilizing a strategic approach, you can negotiate the best possible rates without forfeiting on quality. A key factor is in-depth research into diverse CNC machining shops and evaluating their pricing structures, turnaround times, and capabilities. Don't hesitate to call for quotes from multiple vendors, delivering clear specifications for your project. Remember, honesty is vital throughout the process, as it encourages building strong relationships with your chosen machining partners.

Stable and Correct CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its high-tech software and long-lasting hardware, empowers manufacturers to achieve outstanding levels of accuracy and repeatability in their production processes. This unwavering precision is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances maintains optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in trustworthy machine tools and collaborate with skilled engineers who can fine-tune programs for peak capacity.

All-Inclusive Service CNC Machining Center

A state-of-the-art full-service CNC machining center provides a wide assortment of fabrication functions. These centers house advanced computer numerical control (CNC) devices capable of precisely fabricating components from diverse materials such as polymers. From prototyping to finalizing, a full-service CNC machining center offers bespoke solutions meeting the unique expectations of various industries.

- Sectors covered by full-service CNC machining centers include transportation and customer goods manufacturing.

- The merits of utilizing a full-service CNC machining center deliver exactness, prompt execution, and economic efficiency.

Your Partner in Precision CNC Solutions

When precision is paramount, you need a partner who understands the intricacies of your projects. We are your trusted consultant for all CNC machining capabilities. Our team leverage state-of-the-art equipment and established techniques to deliver excellent results that satisfy your demands. From prototyping to production runs, we are committed to providing reliable service and outstanding customer support every step of the way.

cnc machining services